A Bucks County mill is reborn*

Story and Photos By

Lynne Goldman On December 6, 2011

There are over four dozen roads and streets in Bucks County with the word "mill" in their names: Mill Creek, Mill Pond, Mill Valley, Millbrook and Mill Road (over two dozen alone) to name a few. But in fact there haven't been any active grain mills in the county for decades. Until now.

Now it's Fischer's dream to restore the mill. He's already producing stone ground whole wheat flour and cornmeal using two portable mills set up in his barn under the name Castle Valley Mill. There the wheat is first separated from the chaff--the dry, scaly protective casing around the grain seed--cleaned, and prepared for grinding. (Yes, that indeed is where the expression comes from.) Then using large, thick mill stones the grain is ground. The mill stones sit horizontally in a cast iron casing almost resting on each other, with only a paper thin clearance between them. In fact, if the stones are too close, you can smell it, says Fischer. Hence the expression, "keeping your nose to the grindstone." The stones have furrows and lands, deep rows in their surface that have to be dressed, or sharpened by hand. One mill grinds whole wheat, the other grinds corn, and produces both cornmeal and coarser grain for grits and polenta.

The mill sits next to the Neshaminy Creek not far from Delaware Valley College in Doylestown Township. It was last in use as a water-powered mill in 1922 but became obsolete when steam engines took over powering mills. The modern grain mill was born but the unique taste and nutrition of stone ground grain was the victim, says Fischer. With industrialization came the goal of creating fine white flour. Unfortunately that process uses too much heat and the vitamins are literally cooked out of the grain. This is why all supermarket flour is "enriched" with vitamins and the desire for "white" flour is why bleaching is often used.

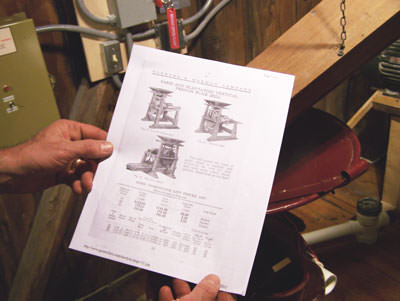

Fast forward to September 2010. Fischer sold his business in the aviation industry and, due to a non-compete agreement, found himself with some time on his hands. After attending a workshop in millwork, he set himself to refurbishing several portable mills, from the inside out. Looking up the original patent applications from the mid- to late-1800s, he tore apart the mills, cleaned and sandblasted the cast iron and put them back together. The mills are now powered by a 10 horsepower engine and produce whole wheat flour, cornmeal and grits/polenta, all from locally grown wheat and corn. The wheat makes great flour for pastry and the grits, well, Fischer says he has Southerners as customers who send it back home to grateful family members.

I had to taste it for myself, of course. Fran Fischer handed me a two pound bag of Castle Valley Mill's whole wheat flour and said, "It makes the best pancakes. Really." I was dubious. Whole wheat pancakes? But I love big fluffy buttermilk pancakes, I whined. But I made the pancakes, using the recipe provided by the Fischers, tied to the cloth flour bag. After setting them down on the table, I discovered we were out of maple syrup. We improvised, eating some plain with butter and some with jam. I'm glad we were out of syrup because we were really able to taste the pancakes. What emerged was tremendous taste and texture. Complex taste. It made us realize that most pancakes are really just a bland platform (or excuse) for lots of butter and syrup. So this is what freshly ground flour tastes like, I thought. And what "stone ground" really means. It's not just a marketing tactic. And along with taste comes quality and nutrition--"real food," says Fischer.

Fischer plans to have the water-powered mill up and running by this spring. As for grinding organic and non-GMO (genetically modified) grains, he's still looking for a good local source, preferring to buy local over organic. If he can find it, he'll set up a separate mill for the organic flour.

You can buy the flour at The Larder and Market at Del Val, both in Doylestown. You can also buy the flour direct online. The cost is $6 for a 2 lb. bag. Once the water-powered mill is running, Fischer will be able to buy the grain in larger quantities which may bring his costs down. This winter he'll also be working on a wholesale business, reaching out to restaurants, bakeries and food professionals.

In the meantime, go buy some Castle Valley Mill whole wheat or cornmeal, and see what freshly ground flour tastes like.Mark and Fran Fischer's house sits next to a mill on property bought by Mark's grandfather in 1947. His grandfather's dream was always to restore the mill, originally built in 1730, to working order. He never achieved this in his lifetime but he did collect--and probably saved from oblivion--mill parts from all over the county. Walking through the mill with Fischer feels a little like walking through the Mercer Museum. Mill stones--and they are big and heavy--lean up against the walls, some as big as four feet in diameter. Portable mills, so called because the cast iron machines are smaller than the larger, water-powered mills, are scattered throughout the building along with other parts, ready for use in the water-powered mill. Most date back to the late 1800s.

* Excerpted by permission. For more photos and the full story, see www.buckscountytaste.com